Montana is not a state known for its dairies. In fact, you could probably count all the dairies – both cow and goat milk – on one hand. When you’re the only goat dairy and cheese manufacturer in west central Montana, you get noticed.

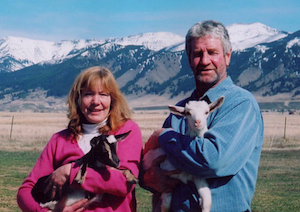

At Amaltheia Organic Dairy, Belgrade Montana, Mel and Sue Brown milk between 250 and 280 goats and produce award-winning organic cheeses that are sold across the United States. While the dairy and cheese plant may be small by some standards, size makes no difference when it comes to careful and sanitary handling of food products.

At Amaltheia Organic Dairy, Belgrade Montana, Mel and Sue Brown milk between 250 and 280 goats and produce award-winning organic cheeses that are sold across the United States. While the dairy and cheese plant may be small by some standards, size makes no difference when it comes to careful and sanitary handling of food products.

“Our cheeses are not only attractive and taste good, they are healthy and safe to eat,” says Sue.

Operational Cleanliness

Small operations like Amaltheia Organic Dairy can develop and implement safe handling practices in day-to-day operations. It begins with attention to herd health. Are the animals healthy; are they clean? Are they washed well for milking? Then the milking parlor – is it clean?

Daily cleanliness is paramount! As Sue says, “You have to be a little anal about it.” In her operation, they start out each production day with cleaning and sanitizing all the tools and equipment that will be used for cheese making. The workspace and tools are sanitized between each product and the floors are washed several times during the day.

State and Federal Inspections

Food processing operations are regularly tested by both state and federal agencies because milk and milk products are the perfect medium in which to incubate bacteria. Montana’s Department of Livestock, Milk & Egg Bureau, and the FDA are responsible.

Samples from every tank full of milk are sent to the state testing lab from Amaltheia, and state inspectors come to the plant to collect cheese samples twice a month. Federal inspectors generally come to the plant once a year, do a visual inspection, and remove cheese samples for testing.

Passing the Test

On a busy workday in early September, 2010, FDA inspectors made their “routine” visit to Amaltheia. Garbed in hazmat suits, hair nets, face masks, and disposable gloves and booties, a team of inspectors examined the small cheese processing plant from top to bottom. They stayed 2 ½ days and collected 160 swab tests for chemical analysis.

On a busy workday in early September, 2010, FDA inspectors made their “routine” visit to Amaltheia. Garbed in hazmat suits, hair nets, face masks, and disposable gloves and booties, a team of inspectors examined the small cheese processing plant from top to bottom. They stayed 2 ½ days and collected 160 swab tests for chemical analysis.

The result? Once again Mel, Sue, and their cheese company passed with flying colors. In fact, they’ve been making cheese for 11 years and never failed a test.

There are training programs at the federal, state, and local level for safe handling of food products. The Browns recommend taking HAACP (Hazard Analysis & Critical Control Points – a preventative approach to food safety) training and developing SSOPs (Sanitary Standard Operating Procedures) from the very beginning; and make GMPs (Good Manufacturing Practices – quality management systems) part of your processes.

Sue’s advice? If you want to be safe, you have to be meticulous with the cleaning. Clean and sanitize as if an inspector will be walking in any moment.

Safety Is the Cost of Doing Business

Is such intense inspection intrusive? Yes, it takes time, but according to Mel, “There definitely needs to be inspections. Whether you are large or small, you need to know the regulations. Milk is a delicate product and people make mistakes; no one is infallible. We want to make sure we are putting out a good healthy product. Everyone wants safe food.”

Implementing good safety procedures requires effort and expense, but for a well-run dairy and cheese manufacturer like Amaltheia Organic Dairy, it is simply the cost of doing business. Sue notes, “Here in Montana, we have the same requirements as the large operations. We have to have Grade A facilities, we pay for the safety inspections and the inspectors, and we have organic certification and inspections as well. We have pretty much the same kind of expenses that a large commercial dairy has, it’s just a larger proportion of our income to cover those expenses.”

Good Food Does Not Make You Sick

When a scientist becomes a farmer, he is keenly aware of safety and sanitation rules; Mel is trained as an embryologist. Bacteria are everywhere and when the wrong kind shows up in milk and cheese, it is serious. “If you have Listeria, you have a problem – a big problem,” he points out. “Listeria can make you sick, very sick.”

Farmers like Mel and Sue Brown want to make sure they are putting out a good, healthy product. And they want it always to be safe!

Farmers like Mel and Sue Brown want to make sure they are putting out a good, healthy product. And they want it always to be safe!

About Amaltheia Organic Dairy

Mel and Sue have more than 500 goats and milk between 250 and 280 every day – twice a day. Each goat produces about three-quarters of a gallon of milk a day, and together they deliver more than 1000 pounds of milk each week.

Sue makes several hundred pounds of cheese a week. Altogether, there are 17 kinds of cheese with the Amaltheia brand on them; some are fresh (ricotta, chevre, and feta) and some are aged.

Amaltheia Organic Dairy cheese can be found on both coasts in health food and grocery stores and in restaurants around the country, or it is available on Amaltheia Organic Dairy’s website.

Dear Sue and Mel Brown.

Listex P100 is the answer to control of Listeria monocytogenes. As a former listeriosos patient I know how terrible this disease can be, do you realize you suffer for years? Though I am happy I survived, I want to help avoid unnecessary suffering. Now I heard the USDA has okayed LISTEX as Processing Aid against Listeria. You can read about this in the news if you Google it, i.e. http://www.infectioncontroltoday.com/news/2011/05/usda-approves-listex-as-processing-aid-against-listeria.aspx. There is no more excuse for Listeria in your dairy products, meat and fisch.

The website of the company which produces Listex is http://www.micreosfoodsafety.com .

If possible I would like to know how food producers could be forced to ban Listeria. Please drop me a line on my e-mail g.van.der.feltz@ziggo.nl

Sincerely yours,

Gustaaf van der Feltz