(Click on any image to see a larger view.)

Starting, growing, and maintaining a small family business is tough, regardless of the industry you are in. Even the bravest and smartest entrepreneur is climbing a steep mountain: one-third of new ventures close within two years, half within five years, and so on. Only one in four is still around 15 years after opening day.[1]

Loki Fish Co. has been going strong for more than 35 years, and has evolved from a single fishing boat to a vertically-integrated, direct marketing company selling a wide variety of fresh, frozen, and processed fish products in Washington, Oregon, and northern California, as well as through an online store and online resellers.

Small food-based businesses like Loki have a special role; they bring diversity, innovation, sustainability, and vitality to local and regional food systems. Big commercial fishing operations must compromise quality in exchange for cost, degrading the value of the food they deliver.

Small Businesses Challenges

While Loki has overcome the odds – through skill, intuition, and luck – and has built a growing business, starting and successfully running a small business means avoiding “killer” challenges every day. The most common causes of business failure fall into four areas: Finance, Marketing, Operations, and Management.

Finance – The Money

- Inability to acquire or leverage capital for growth and/or operations

- Poor accounting practices

- Poor cash flow and poor cash management

Marketing – The Customer

- No real differentiation in the market, lack of a unique value proposition

- No customer attraction plan

- Poor execution/ineffective marketing tactics

- A declining market and or increased competition

Operations – The Product

- Wrong location (retail-based businesses)

- Operational mediocrity, including bad service

- Operational inefficiencies

Management – The People

- Inability to identify a profitable business model with proven revenue streams

- Lack of experience

- Out of control growth

- Dysfunctional founder/management

Small Boat Fishers Face Special Challenges

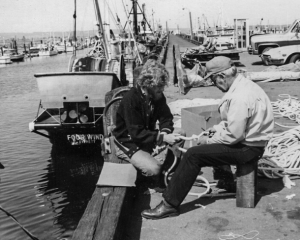

Like small family farmers, small boat fishers like Pete Knutson and his family not only harvest their product, they have to carefully handle it, process or package it, and take it to market.

And like small farmers, small boat fishers must deal with Federal, state, and local regulations and requirements; complex food safety and handling requirements, pricing that benefits multiple middlemen, and a convoluted supply chain that often seems determined to keep them out of the marketplace altogether.

Launched in 1979, with a single boat, the F/V Loki, Pete began gillnet fishing in the Clarence Strait of southeastern Alaska and in Washington’s Puget Sound.

His wife and partner Hing Lau Ng managed the business, kept the books, and secured the home port. Two sons, Jonah and Dylan, grew up to become integral parts of the family business; Jonah fishes from the Loki (Pete now captains the Njord) and Dylan runs the land-based parts of the business, still with Hing’s help.

The small boat fishing community in Puget Sound was at one time a major supplier of fish to the cities, towns, and villages that ring the Sound. The coming and going of the fishing fleet was part of the region’s lifeblood, and fresh, smoked, dried, salted, and pickled fish was a rich food source.

Today, small boat fishers are continually threatened by huge commercial fishing operations whose goal is to catch as much fish as they are allowed as quickly as possible. Fishing has become a commodity business in a global market place where cost is the driving factor.

Operations made up of huge boats, networks of tenders collecting the catch from each boat, and “on-the-water” processing plants can’t focus on careful handling to maintain quality and taste when the speed of the catch and processing is paramount.

At the same time, recreational boats (including yachts up to 120 feet long) now compete for slips at Seattle’s Fishermen’s Terminal, once the home port for the mooring and maintenance of 600 fishing boats.

Loki’s Success – How It Came About

Loki Fish Company, though now selling more than $1 million worth of fish a year, is still a small business by any measure. Loki buys fish from 4 boats (manned by 4 captains and 6 deck hands) and sells direct to consumers, restaurants, and retailers. Seattle’s land-based crew amounts to 3 full-time employees, 3 part-time employees, and 6 farmers market helpers. In Alaska, there are 3 part-time hands who stage totes, load and drive trucks, and help with errands.

The bulk of the harvest comes from fishing in southeast Alaska between mid to late June and mid to late August, although some of the boats may stay through mid September, depending on the weather and the catch. In Puget Sound, from mid October to mid November, the catch consists of Keta salmon every year and Pink salmon every other year, on the odd-numbered years.

1980s

The 1980s was a decade of profit and promise, though it remained one man, his mate, and one boat fishing in Clarence Strait, off southern Alaska.

Pete would ship Sockeye and Coho salmon to Seattle via Alaska Airlines. Then Hing and the boys would collect the fish at the airport, stop at the closest 7-Eleven to pick up cubed ice to keep the fish chilled, and deliver it to Pure Food Fish Market at Pike Market. Fresh fish were also flown directly from Ketchikan, Alaska, to San Francisco, where it was delivered to another small market.

Loki Fish Company was generating a profit, the family was growing, and the future looked bright.

1990s

Loki’s business model remained the same in the 1990s – one boat fishing and the family to pick up the catch at the airport and move it around. But there were road blocks developing and pressure on pricing that cut into margins and made it more difficult to sell fresh fish from Alaska:

- The 1989 Exxon Valdez oil spill in Prince William Sound damaged salmon habitat in south Alaska, and the public became concerned about the quality and safety of wild salmon.

- By the end of 1990, world farmed salmon production reached 325,563 metric tons, a 4,600% increase from 1980, and farmed salmon made up 26% of the world salmon market. That huge volume of farmed salmon pushed down the price of wild salmon.

- Large seafood distributors began to realize that Loki was selling high quality salmon directly to retailers. The distributors began to pressure retail buyers by threatening to pull their full line of products out of a store, if the retailer bought Loki salmon.

Consumer concern about wild salmon caught in Alaska, increased competition from farmed salmon, and a supply chain controlled by large distributors came together in a “perfect storm” requiring new solutions from Pete, Hing, Jonah, and Dylan.

2000s

In the 2000s, Jonah (the elder son) took over the F/V Loki and Pete started running the F/V Njord, a slightly larger boat. Besides selling fresh fish, the family was learning how to build up an inventory of frozen product to balance seasonal sales.

Seattle’s farmers markets are Loki’s most visible sales channel.

During the decade, Loki started selling direct to consumers at Puget Sound farmers markets, offering products like smoked chum, renamed Keta, at 13 weekly markets. “If the distributors were going to cut us out, we decided to just do without a distributor anyway. We’ve always functioned without a lot of infrastructure, so going with a direct model made sense,” said Dylan (the younger son, and now Loki’s general manager).

Supporting direct sales required an Internet presence, and Loki developed an attractive website and supported online sales with a digital storefront. Telling the Loki story and showcasing Loki products online also attracted a number of online resellers and increased the company’s ability to do business with a wider customer base.

Dylan began experimenting with different sales channels, however he can track most of them back to Loki’s farmers market presence. “We have a number of different channels and the big connector has been our presence at the area farmers markets,” Dylan said. “I can look down our list of resellers and wholesalers and most of them do business with us because of connections we made at farmers markets or because our brand is aligned with the farmers market movement.”

It was a tough decade; Loki built a solid, recognizable brand, but still hadn’t built a solvent business.

Today

Around 2010, Dylan reached a turning point; after more than 30 years the Loki Fish Company was still operating out of the Knutson’s garage and backyard. “We were working with secondary processors to get everything done but the log jam in the back yard and the alley was unbelievable. I don’t think that anyone who knew our brand had any idea how backward the operation really was,” Dylan admits. “I told my family that we needed to get a commercial warehouse or I was going to move on to a different profession because things were so out of control in the summer.”

The company hit a cycle where the fish on hand ran out every spring before fishing season reopened – in other words, an infrastructure with capacity and not enough inventory – and something had to change.

In the last few years, Dylan and the Loki team have made three major changes to improve sales and profitability:

- Loki now has 4 boats on the water – the F/V Loki, F/V Njord, F/V Fram (captained by Mark Johansen, longtime former deckhand of Pete’s), and F/V Mount Royal (captained by Byron Spence, another former deckhand) – and buys selected “frozen at sea” salmon from F/V Charity out of Sitka, Alaska (captained by Martin Gowdy).

- The company has cut farmers market presence to 4 year-round markets, eliminating its sales at 9 less profitable and more labor-intensive markets, thus maintaining inventory for more profitable sales.

- Carefully balancing fresh fish sales in the summer to keep cash flow going and paying the bills while freezing and processing enough product for the off season.

“To keep all markets in balance is always a changing dynamic,” Dylan says. “Working with more boats and having more fish stabilizes our inventories and makes us a little less vulnerable.”

Loki: A Different Way of Doing Business

Through skill, intuition, luck, and lots of hard work, Loki has built a recognized brand and successful business by meeting and overcoming the most common causes of business failure.

Finance – The Money

Capital for growth and/or operations.

Having come from a boat-building family, Pete was able to acquire the Loki without taking on a large amount of debt. Since then, the company has been primarily self-funded with a little help from family and friends.

Cash flow and cash management.

Until the mid 1990s, cash flow was fairly stable and the company was profitable. As the salmon market became flooded with farmed fish, Loki’s profits tumbled. To prepare for the coming change in the market, Pete returned to school to complete his PhD and started teaching at Seattle Central Community College to teach during the winter and supplement the family’s income.

In the mid-2000s, Dylan – as general manager – made substantial changes in sourcing fish (going from 2 boats to 4, and then sourcing from others as the opportunity arises ), eliminated less profitable sales channels, and balanced the inventory of fresh, frozen, and processed (canned, smoked, and pickled) fish. These changes contributed to consistent, profitable growth.

Dylan also added food service in Loki’s farmers market stands, delivering premium high profit margin, value-added products such as soups, salads, sandwiches, and entrees featuring Loki fish.

Marketing – The Customer

Unique value proposition.

In the face of competition from a huge commodity-based commercial fishery in a global market place, Loki Fish Company is positioned as, “Sustainably harvesting and direct-marketing wild fish, with integrity from sea to table.”

While Loki offers a high quality, premium product handled responsibly to preserve quality and flavor, the company is very open and transparent about their story and the stories of their fishermen.

“I don’t want to buy totes of fish from brokers, then reprocess it and put our logo on it. We have specific handling, processing, and storage methods that our fishermen follow. We want to be transparent about what we’re doing,” says Dylan. “We work directly with our fishermen to offer them a consistent price so they can make a fair living. The food industry is brutal and the people who work the hardest to produce good food are the ones facing the most unstable pricing.”

Sophisticated web site and online storefront.

While Loki was struggling for profitability and dealing with a limiting and labor-intensive infrastructure, the company was building a strong web presence. Aided by a family friend who is an experienced marketing professional – and willing to work pro-bono – the website gave this small company a big look.

In 2004, the first website was launched introducing Loki Fish Company to prospective customers outside its network of farmers market sales days. Updated in 2008, an online store was added with options to deliver selected items nationally.

Social media – Facebook, Twitter, and a blog – were added in 2009, giving Loki better communication with – and a closer connection to – its customers.

The entire site was rebuilt and a sophisticated storefront launched in mid 2015. Once again, this little company’s website has a “big company look.”

Consistent farmers market presence.

Since the early 1990s, Loki products have been sold at Puget Sound farmers markets. At one point, you could find Loki at 13 markets a week during the summer, on any day except Monday. While maintaining such as strong presence at farmers markets build brand recognition and sold a lot of product, it pushed the staff hard. Now Loki is at the area’s 4 year-round markets, which take place on Saturday and Sunday.

Some of Loki’s many fish products.

Some of Loki’s many fish products.

Direct sales at farmers markets connect Loki to a large base of consumers, at the same time the high quality of Loki fish and the company’s commitment to the independence and creativity of the farmers market movement, attract a wide variety of sales channels including online resellers such as Amazon.com and Chefshop.com. The farmers markets have been the key connection.

Expanded wholesale: online and offline resellers.

Loki has developed partnerships and relationships with restaurants serving everything from seasonal salmon pizza to plates of grilled salmon, fish markets and supermarkets, and even online retailers like Chefshop.com and Amazon.com.

The company has a cross-docking agreement with Co-op Partners Warehouse, a Midwestern distributor of natural and organic food.

While Loki is still a small Seattle-based company, they are now reaching customers nationwide through a network of resellers that reaches across the country.

Operations – The Product

Delivering a quality product.

High volume commercial fisheries must handle fish as little as possible and move them through the distribution channel as quickly as possible. To do so requires a lot of mechanization and automation, which means that fish can be crushed or bruised during handling.

“Sockeye salmon are pretty resilient,” says Dylan, “they can get beat up pretty well and you can still get an acceptable fish to the retail shelf at a lower price.” On the other hand, Pink salmon must be handled carefully to maintain a high quality. According to Dylan, chum salmon (Keta) “have a lot of blood in them” and they get an off taste – gamey – if they’re not bled and cleaned right away.

Left: Filleting whole salmon. Right: Breaking down a 100-plus pound halibut.

Loki Fish Company’s brand equity is built on high quality. Consumers will buy the fish if the quality is better, restaurants will by the fish if it is consistent and has better shelf life. It is the labor-intensive handling that has established Loki’s niche in the market.

Overcoming operational inefficiencies.

It was Dylan’s announcement, a little over 5 years ago, that he was going to find a new career if something wasn’t done to improve control over the internal distribution and handling of the volume of fish coming from Alaska in the summer.

Inefficient handling threatened to take down the company and the opportunity came to sublet a small warehouse and processing facility, not far from Seattle’s airport. Streamlined movement of fresh fish coming from Alaska and simplified distribution for farmers market sales and to wholesalers and retailers along the I-5 corridor eliminated errors, redundancy, and delayed handling.

Management – The People

Overcoming lack of experience.

Pete did not come from a background in the seafood industry or seafood sales, his family were ship builders. He began fishing as a young man and learned the business from the water up. Loki Fish Company was not built on “best practices” or “a 20-year business plan,” it was built slowly and carefully.

While the company may have grown more quickly and become profitable sooner with industry and market experience, Pete and his family were willing to learn, gained expertise as they went along, avoided serious mistakes, and got better at managing the business.

The goal the entire time, was not to build a big company, but to be able to offer a reliable price to the fishermen catching the fish, to take good care of the fish and the environment, and to deliver a good product.

Managing growth.

Enthusiasm for new and innovative products can cause a company to extend a product line too far, too fast. As Dylan reduced the number of farmers market days, there was more time to experiment with new products, like salmon sausage. As a result, the product line grew in diversity before the company developed an economy of scale to support it.

In response, Dylan has focused on identifying redundant or slow-moving products and control the number of products offered. He says, “You can get to a point where you think you have to have everything. Then when you get drop something, you find you’re so much more efficient. And you’ll discover that it’s not really missed.”

In response, Dylan has focused on identifying redundant or slow-moving products and control the number of products offered. He says, “You can get to a point where you think you have to have everything. Then when you get drop something, you find you’re so much more efficient. And you’ll discover that it’s not really missed.”

The key is to scale smartly and strategically.

Advice to Aspiring Entrepreneurs

Dylan was born into and grew up in the family business, and he has ben instrumental in Loki’s growth. His advice to someone wanting to start a small food-based business is honest and to the point. He says:

- Look at what other people are doing. What are they doing that you like?

- Be prepared to throw your hat in the ring completely; you had better have a passion for what you’re taking on.

- Be willing to give up what a lot of other people value in terms of a “normal” lifestyle.

- If you want to get into a direct marketing business that has integrity behind it and involves some kind of vertical integration, you have to be willing to let the work/life line dissolve to some degree.

- If you want to direct market a seasonal product, you’ll need to find a way to sell something in the off season. That requires a lot of communication and logistics. It’s easy to run up the bills pretty quickly and to lose sight of the down time.

- To try to find fun in working and have passion for it, otherwise you just won’t make it. It’s amazing how much energy it takes, and how a lot of it is just powering through tough times.

- Try to stay on top of it. When you have built something up that you are proud of, you can keep going. Sometimes you just have to keep plugging away at it every day

“I usually say my job is doing everything outside of catching the fish and delivering it to the dock; I’m coordinating everything else. I don’t have to worry about running a boat, though I’m very close to the fish. And I know the fish really well,” says Dylan.

Our Recommendations

Small food-based businesses like Loki Fish Company have a special role in our food system: they bring diversity, innovation, sustainability, and vitality to our local economy. As consumers, when we talk about good food, so often we forget that responsibly caught wild fish are an excellent value.

Puget Sound’s small boat fishers are critical to our local and regional food systems and deliver high quality products, while big commercial fishing operations must compromise quality in exchange for cost, degrading the value of the food they deliver.

At GoodFood World, we support and encourage small boat fishers like Loki and provide consulting and advisory services to a wide range of small food-based businesses. While Loki is a great example of a successful small family business, we see points where changes could have lead to success sooner:

- During the company’s early growth stages, Pete could have explored alternative funding sources for additional capital to improve the Loki’s operations.

- A move to a small commercial processing plant should have been made sooner. The physical constraints of working in inefficient and limited space required outsourcing more processing to third parties. Limited and poorly organized space can contribute to added labor, redundancy, waste, and potential safety problems.

At the same time, we see opportunities Loki can explore for future sales and brand development:

- Loki’s process and presence at the 4 year-round markets could be leveraged to add a CSF (community supported fishery) or buying club to the existing sales channels. Logistics are already in place to facilitate customer collection of products.

- To extend the brand consider a “Loki Inside” relationship with a food processor of soups, spreads, or other quality packaged ready-to-eat products.

- Partner with restaurants for seasonal promotions to bring the Loki name forward. In the fall, at the end of the summer season, consider various “festival” promotional opportunities. For example, pair the Keta or Pink harvest with a Beaujolais nouveau

- Add QR codes to labels to provide “real life hyperlinks” to more information to keep the Loki story fresh and immediate at the point of purchase.

- Partner with other small boat gillnetters harvesting Keta to brand Keta as an affordable, high value fish for the whole family. Key points:

- Ecosystem values: sustainable fish, strong fishery, Puget Sound’s most abundant wild salmon

- Keta is mild and firm, containing less oil than as Coho or Sockeye salmon. It has a lighter flavor and pairs with sauces well.

- Keta is an economical choice, it is affordable and cooks quickly.

- Keta are extremely low in pollutants because they “eat lower on the food chain” and thus consolidate fewer contaminants than larger fish.

- Keta also spawn and hatch in small streams and intertidal zones and migrate offshore soon after emergence, avoiding pollution that can be present in freshwater.

More Information

For more information about Loki Fish Company and their products, go to www.lokifish.com.

For more information about GoodFood World’s advisory and consulting services for small food-based businesses, go to www.goodfoodworld.com/services. Whether you want to develop a new product, launch a new business, expand your supply chain, or focus on an urgent problem, we are here to help.

[1] (Bloomberg, http://www.bloomberg.com/bw/articles/2014-07-28/study-failed-entrepreneurs-find-success-the-second-time-around)